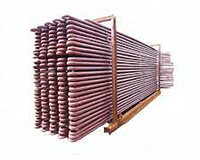

Pipingprojects.us is one of the leading Boiler Tube Manufacturer in Texas. The passage of both liquid and vapor is accomplished using boiler bank tubes. It is frequently necessary to bend multiple boiler tubes to bigger radius due to the different sizes and forms of the tubes in order to avoid aberrations, fine lines, and outside cracking. As so, the boiler's duration is extended, which adds to its convenient and effective functioning. Pipingprojects.us is also a well-known Boiler Tube Supplier in Texas.

Boiler Tube

Seamless

Seamless

Welded

Welded

Round

Round

Trusted

Supplier

Genuine

Product

Easy

purchase

Want to know more about product?

Contact us now for quick help

Why are Pipingprojects.us the best Boiler Tube Manufacturer & Supplier in Texas?

Following strict quality control procedures and standards that guarantee good surface and near dimensional tolerances, we manufacture boiler tube. With ASME Quality and ISO 9001:2015 Certifications, we are a market-leading supplier of carbon steel, alloy steel, and stainless steel boiler tube solutions on a global scale. We not only produce stainless steel boiler tube of the highest quality, but we are also an authorized dealer of ISMT and Jindal for the supply of carbon steel and alloy steel boiler tube.

Pipingprojects.us is a leading Boiler Tube Supplier in Texas. Our products are in various diameters and sizes to meet different needs and purposes.

Want to know more about product?

Contact us now for quick help

Leading Boiler Tube Suppliers in Texas – Stainless Steel Boiler Tubes

Boiler Tubes of enhanced strength, crafted from stainless steel, are utilized across a broad spectrum of operations to heat liquids and generate steam. These tubes are designed to withstand extreme levels of tension and temperature, rendering them ideal for use in conjunction with stainless-steel boilers. In such boilers, fluid is heated while circulating within the tubes.

Stainless steel boiler tubes are produced as both soldered and continuous pieces. Heated steel preforms are moulded into the appropriate shape by being extruded through a metallic die, creating SS Seamless Boiler Tubes. We stand for on-time deliveries of high-quality Boiler Tube Manufacturers in Texas.

Boiler Tube - Specifications

Pipingprojects.us is an esteemed Boiler Tube Manufacturer, is dedicated to providing with reliable, top-notch Boiler Tube. Here are the specifications for Boiler Tube.

| Particulars | Specification | |

|---|---|---|

| Tube Size (OD and WT) | e.g., 2 inches OD x 0.25 inches WT | |

| Length | e.g., 20 feet or as per customer requirements | |

| Heat Treatment | Annealed, Normalized, Quenched and Tempered, etc. | |

| Pressure Rating | e.g., 3000 psi, 6000 psi, or higher | |

| Temperature Rating | e.g., Up to 600°C (1112°F) or higher | |

| Surface Finish | Smooth, Pickled and Passivated, Polished, etc. | |

| Grade | ||

| Stainless Steel | 200 Series - 201, 202, 205.

300 Series 301, 302, 303, 304, 304L, 308, 309, 309S, 310, 310S, 314, 316, 316L, 316TI, 317, 317L, 321, 347. 400 Series 405, 409, 429, 430, 430F, 430FSe, 434, 436, 442, 446, 403, 410, 414,416, 416Se, 420,420F, 422, 431, 440A, 440B, 440C. 500 Series - 501, 502. 600 Series - 630 (17-4 PH). |

|

| Hastelloy | C22, C276, X, B-2. | |

| Monel | 400, K500. | |

| Nickel Alloy | Nickel 200 Nickel 201, Alloy 20, Alloy 286, Alloy 218 (Nitronic 60), Nitronic 50 (XM-19). | |

| Cupro Nickel | Cu 90-10 (C70600,CW352H), Cu 70-30 (C71500, CW354H). | |

| Inconel | 601, 625, 660A, 718, X-750, 825, 925, 608. | |

| Duplex / Super Duplex | D S31803, D S32205, SD S32750, SD S32760, SD S32950. | |

| Nichrome Alloy | CrNi 20/80. | |

| Copper | ASTM B1, ASTM B2, ASTM B3, ASTM B152, ASTM B124, ASTM B133. | |

| Brass | Alloy 260, Alloy 272, Alloy 330, Alloy 353, Alloy 360, Alloy C48200 - C48500, Alloy 464. | |

| Bronze | Alloy 954, Alloy 933. | |

| Mild Steel | Sae 4118, Sae 4120, Sae 4120, Sae 4130, Sae 4135, Sae 4137, Sae 4140, Sae 4142, Sae 4145, Sae 4147, Sae 4150, Sae 4161, Sae 8620. | |

What is Astm A178 Boiler Tube?

ASTM A178 standard covers ERW tubes with a minimal wall width. These tubes are utilized in various applications such as boiler tubing, boiler ventilation systems, superheater vents, and safety terminals. The ASTM A178 Boiler Tube is composed of carbon steel and carbon-manganese alloy steel. The manufacturing process requires heat treatment and welding upon cooling.

The ASME SA178 Tubing sizes and wall thicknesses conforming to this specification range from 0.035 to 0.320 inches (0.9 to 9.1 millimeters), inclusive, in minimal wall width. Pipes of other sizes are acceptable provided they meet all other specifications of this specification. ASME SA178 Carbon Steel Boiler Tubes with an internal diameter and thickness of less than 1/8 inches [3.2 mm] or 0.015 inches [0.4 mm] are examples of the specifications for mechanical characteristics.

Boiler Tube Weight Chart in Mm, Kg, Pdf

| Nominal Size (inches) | Outside Diameter (inches) | Wall Thickness (inches) | Weight per Foot (lbs) | Weight per Meter (kg) |

|---|---|---|---|---|

| 1/2 | 0.84 | 0.083 | 0.67 | 0.25 |

| 3/4 | 1.05 | 0.095 | 1.03 | 0.38 |

| 1 | 1.315 | 0.109 | 1.71 | 0.64 |

| 1-1/4 | 1.66 | 0.109 | 2.14 | 0.80 |

| 1-1/2 | 1.90 | 0.109 | 2.46 | 0.92 |

| 2 | 2.375 | 0.109 | 3.05 | 1.14 |

| 2-1/2 | 2.875 | 0.120 | 4.64 | 1.74 |

| 3 | 3.50 | 0.120 | 5.66 | 2.12 |

| 3-1/2 | 4.00 | 0.120 | 6.49 | 2.43 |

| 4 | 4.50 | 0.120 | 7.30 | 2.73 |

| 5 | 5.563 | 0.134 | 10.79 | 4.03 |

| 6 | 6.625 | 0.134 | 12.84 | 4.80 |

| 8 | 8.625 | 0.148 | 19.33 | 7.24 |

| 10 | 10.75 | 0.165 | 30.58 | 11.44 |

| 12 | 12.75 | 0.180 | 40.49 | 15.17 |

Hot Finished Vs Cold Drawn Seamless Boiler Tubes

Hot, finished seamless boiler tubes undergo processing at elevated temperatures, endowing them with commendable formability. Conversely, cold-drawn seamless boiler tubes are processed at ambient temperatures immediately following the hot rolling process. The cold-drawn tubes exhibit superior strength compared to their hot-finished counterparts, characterized by a shorter processing time. Hot-finished seamless steel tubes and boilers' pipes are normalized and devoid of any internal stress. On the other hand, cold-drawn boiler tubes boast of a precise finish.

Boiler Tube Size Chart in Inches

| Nominal Size (inches) | Outside Diameter (inches) | Wall Thickness (inches) | Inside Diameter (inches) |

|---|---|---|---|

| 1/2 | 0.84 | 0.083 | 0.674 |

| 3/4 | 1.05 | 0.095 | 0.860 |

| 1 | 1.315 | 0.109 | 1.097 |

| 1-1/4 | 1.66 | 0.109 | 1.442 |

| 1-1/2 | 1.90 | 0.109 | 1.682 |

| 2 | 2.375 | 0.109 | 2.157 |

| 2-1/2 | 2.875 | 0.120 | 2.635 |

| 3 | 3.50 | 0.120 | 3.260 |

| 3-1/2 | 4.00 | 0.120 | 3.760 |

| 4 | 4.50 | 0.120 | 4.260 |

| 5 | 5.563 | 0.134 | 5.295 |

| 6 | 6.625 | 0.134 | 6.357 |

| 8 | 8.625 | 0.148 | 8.329 |

| 10 | 10.75 | 0.165 | 10.42 |

| 12 | 12.75 | 0.180 | 12.39 |

Boiler Tube Supplier Design and Equipment Arrangements - Pipingprojects.us

A Boiler Tube is essential in various manufacturing processes, as it is available in multiple specifications. The selection of Boiler Tube material for installation is based on its characteristics, including its resistance to chemicals, temperatures (or temperature fluctuations), pressures, acids, gases, and occasionally electromagnetic or electrical forces. When sourcing, a reliable Boiler Tube Manufacturer in Texas is crucial for ensuring quality and performance.

Boiler Tube Schedule Chart

| Nominal Size (inches) | Outer Diameter (inches) | Wall Thickness (inches) |

|---|---|---|

| 1/2 | 0.840 | 0.083 |

| 3/4 | 1.050 | 0.095 |

| 1 | 1.315 | 0.109 |

| 1-1/4 | 1.660 | 0.109 |

| 1-1/2 | 1.900 | 0.109 |

| 2 | 2.375 | 0.109 |

| 2-1/2 | 2.875 | 0.120 |

| 3 | 3.500 | 0.120 |

| 3-1/2 | 4.000 | 0.120 |

| 4 | 4.500 | 0.120 |

| 5 | 5.563 | 0.134 |

| 6 | 6.625 | 0.134 |

| 8 | 8.625 | 0.148 |

| 10 | 10.750 | 0.165 |

| 12 | 12.750 | 0.180 |

Benefits of Water Tube Boiler Over Fire Tube Boiler

What Is The Use Of Stainless-steel Boiler Vent Pipe?

The stainless-steel boiler vent pipe is a crucial component that facilitates the release of residual gases from the workplace. This action leads to improved airflow and oxygen availability within the unit. Additionally, the use of the stainless-steel boiler flue pipe results in a reduction of carbon monoxide levels within the department. The lifespan of these pipes is estimated to be at least 20 years, and they require minimal maintenance. The ss boiler exhaust tube serves the purpose of transporting gases and hazardous materials that are burned in the boiler outside the facility and discharging them into the environment.

Boiler Tube Diameter

|

Outer Diameter In mm |

Permissible Variations In mm | |

|---|---|---|

| Over (+) | Under (-) | |

| 1 to 1 ½ (25.4 to 38.1), Incl | 0.006 (0.15) | 0.006 (0.15) |

| Under 1 (25.4) | 0.004 (0.10) | 0.004 (0.10) |

| Over 11⁄2 to 2 (38.1 to 50.8), Excl | 0.008 (0.20) | 0.008 (0.20) |

| 21⁄2 to 3 (63.5 to 76.2), Excl | 0.012 (0.30) | 0.012 (0.30) |

| 2 to 21⁄2 (50.8 to 63.5), Excl | 0.010 (0.25) | 0.010 (0.25) |

What is an Alloy Steel Boiler Tube??

In the manufacturing of alloy steel for boiler pipes, many ductile and malleable factors are considered, resulting in exceptional mechanical properties. Alloy steel, which encompasses several significant chemical components such as Ni, Cr, Mo, Si, and B, is a common variation of boiler tubes. Alloy Steel Seamless boiler tubes are frequently crafted using these alloys. The outstanding qualities of alloy steel boiler pipes include rapid weldability, exceptional corrosion tolerance, superior strength, and extended lifespan. Many companies use alloy steel in boiler manufacturing due to its robust resistance capabilities.

Is SS Seamless Boiler Tubes Expensive?

Most boiler piping made from stainless steel is either seamless or welded. The seamless stainless steel boiler tube is considered superior to the welded pipe due to its formation from a single piece of metal. However, the manufacturing process for seamless boiler pipes is distinct, making them more expensive. It is acknowledged that the high cost of this particular alloy is attributed to the presence of molybdenum and its exceptional quality. In contrast, welded boiler piping is generally less expensive than seamless boiler tubing due to its more straightforward manufacturing process.

Most Common Uses For Boiler Tubes

Clients Project Report of Boiler Tube

Pipingprojects.us is a top Boiler Tube Manufacturer in Texas. Our packaging and shipping team guarantees that our products are of excellent quality and have exact measurements. We employ damage-resistant packaging methods to ensure that our products arrive in perfect condition. We are also a leading Boiler Tube Supplier in Texas.

| Product supplied | Cities |

|---|---|

| Boiler Tube Supply | Houston |

| All types of Boiler Tube | Austin |

| Boiler Tube | Dallas |

| Stainless Steel Boiler Tube | San Antonio |

Want to know more about product?

Contact us now for quick help

Application & Uses of Boiler Tubes

Boiler Tube Manufacturer in Texas

Boiler Tube Supplier in Texas