CNC Components Manufacturer & Supplier in USA - Pipingprojects.us

Pipingprojects.us is one of the leading CNC Components Manufacturer in USA. Various grades of stainless steel can be utilized to create CNC Components, enhancing their overall performance. These fittings find utility in both industrial and instrumentation applications. Alongside stainless steel, these fittings can be crafted from alternative materials such as copper, brass, alloy 400, and carbon steel. We are also a well-known CNC Components Supplier in USA.

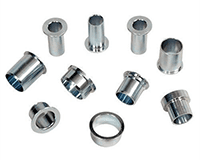

CNC Components

CNC Components Manufacturers - Specifications

- Materials: Titanium, Monel, Nickel, Inconel, Hastelloy, Aluminium tantalum, Zinc, Lead, Copper, Brass, Bronze, Bismuth, etc.

- Size: 10mm to 70 mm

- Tolerance: 0.001mm- 0.005mm

- Thread: UNC / NPT/ BSP / BSPT

Trusted

Supplier

Genuine

Product

Easy

purchase

Want to know more about product?

Contact us now for quick help

Why Pipingprojects.us for CNC tools?

- These fittings are appropriate for utilization in both industrial and instrumentation contexts.

- Compare prices in One Go

- you can Check suppliers profile and their experience of supplying material in Middle East

- No Subscription for Buyers

- you can check here genuine reviews and Ratings

- We post with complete profile and their accreditations

Best CNC Components Suppliers - Types

Pipingprojects.us is a leading CNC Components Supplier in USA. Our products are in various diameters and sizes to meet different needs and purposes.

Our Best Selling CNC Components

Want to know more about product?

Contact us now for quick help

CNC Components Supplier Design and Equipment Arrangements - Pipingprojects.us

A CNC Component is essential in various manufacturing processes, as it is available in multiple specifications. The selection of CNC Component material for installation is based on its characteristics, including its resistance to chemicals, temperatures (or temperature fluctuations), pressures, acids, gases, and occasionally electromagnetic or electrical forces.

CNC Components - Specifications

Pipingprojects.us is an esteemed CNC Components Manufacturer, is dedicated to providing with reliable, top-notch CNC Components. Here are the specifications for CNC Components.

CNC Components Supplier - Specifications, Standard, & Grades

| Product Name |

CNC Component |

| Stainless Steel CNC Machined Components |

ASTM A 182 F 202, 304, 309, 310, 316, 316L, 317L, 321, 347, 904L |

| Duplex Steel CNC Machined Components |

ASTM / ASME / A/SA 182 UNS No. 31803, 2205 |

| Super Duplex Steel CNC Machined Components |

ASTM / ASME / A/SA 182 UNS No. 32550, 32750, 32760, 2205, 2507 |

| High Nickle Alloy CNC Machined Components |

ASTM / ASME SB 524 / 160 / 472 / NIckle 200, NIckle 201, Monel 400, Monel K500, Inconel 600, Inconel 625, Inconel 718, Incoloy 800, Incoloy 825, Hastelloy C726, Hastelloy C22, Hastelloy B2 |

| Copper Nickel CNC Machined Components |

Cupro Nickle 70/30 (70600)

Cupro Nickle 90/10 (71500) |

| Size |

2D AutoCad & 3D Mechnical Drawing as per your requirment |

| Type |

Any Shape & Accurace Size Like turning, Drilling, Different Design (In Milling Machine) |

| Thickness |

Any Thickness |

| CNC Machined Components Capacity |

About 100000 & Above Pc Per Month |

| Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery. |

| Processing |

CNC turning, CNC milling, CNC machining, Grinding, EDM wire cutting. |

| Surface treatment |

Anodizing, brushing, galvanized, laser engraving, silk printing, polishing, powder coating etc. |

Things To Note Before Buying Cnc Components

Grades: The grade of stainless steel refers to its chemical composition and properties.

Choose the correct grade as per your application.

Thickness: The thickness of the CNC Components will affect its strength and weight. Select the

thickness as per your needs.

Finish: The finish of the CNC Components will affect its appearance and how easy it is to clean.

Choose a finish that meets your requirements.

Sizes: The size of the CNC Components will depend on your specific needs.

Temper: The temper of the CNC Components refers to its strength and ductility. Choose a temper

that is appropriate for your application.

Price: The price of CNC Components will vary depending on the grade, thickness,

finish, temper, size, and supplier. Compare the rate from different suppliers before

purchase.

Which is Better?5-Axis CNC, 4-Axis or 3-Axis Machining Parts?

The CNC machining components are engineered to incorporate varying degrees of intricacy in the motion between the workpiece and the cutting tool.

- A 3-axis machining tool is the simplest workpiece fixed in a single position. The spindle's movement can occur in the x, y, and z linear directions. These tools are utilized in the process of machining two-dimensional and two-and-a-half-dimensional geometries.

- 4-Axis has three linear movements, x, y, and z, alongside the A axis due to the rotation of the workpiece. Four sides can be machined using a single fixture setup.

- 5-Axis machining tool utilizes 2 or 3 rotational axes per machine. The machine can utilize the A axis or C axis or use the B and C axes in rotation. There are two types of 5-axis CNC machines: 3+2 or fully continuous 5-axis machines.

Difference Between 4-Axisand 2D – 3D Machined Parts

CNC milling toolpaths are classified as 2D, 3D, and 4axis depending on the number of axes involved when they move.

- The 2D components can solely be machined on the XY plane, with the Z axis serving to position the tool at its required depth. These Precision CNC Machined Components, featuring 2-1, 2D parts, are referred to as prismatic in this context.

- The 3D toolpaths encompass non-prismatic forms, comprising intricate organic shapes. This level of proficiency necessitates more intricate machine movements. In this case, the revolved surface necessitates XZ tool motion, whereas the fillet necessitates XYZ tool motion.

- The utilization of a 4-axis necessitates the installation of an auxiliary rotary component on the CNC machine, positioned in parallel to either the x or y-axis. The toolpaths associated with this level of functionality encompass both 4th axis substitution and simultaneous 4th axis operations.

What are the Common Uses of CNC Components?

- Architecture includes the design and construction of building exteriors, such as facades, roofs, railings, doors, and windows.

- Foodservice includes tables and countertops, sinks and appliances, and food preparation equipment.

- Industrial: Chemical processing equipment, pharmaceutical equipment, marine equipment, oil and gas

equipment.

- Other: Manufacturing Automation, Energy Management, and Application.

Application & Uses of CNC Components

- Sugar Industry

- Power Industry

- Shipbuilding Industry

- Mechanical and Plant engineering

- Food, Beverage, and Dairy

- Oil and Gas Plant

- Process Instrumentation

Supplying CNC Components to Following Cities:

Pipingprojects.us is a leading CNC Components Supplier in USA. We proudly supply high-quality CNC Components to major U.S. cities. We have dominated the market as a leading CNC Components Manufacturer in USA for a long time.

Cities We Supply in USA

| Cities We Supply |

| New York |

Chicago |

Los Angeles |

San Diego |

San Francisco |

|

Seattle |

Dallas |

Houston |

Austin |

Phoenix |