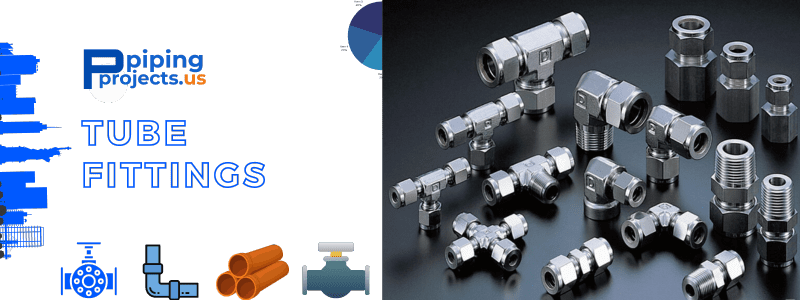

Pipingprojects.us is one of the leading Tube Fitting Manufacturer in USA. Various grades of materials use manufacture Tube Fittings, enhancing their overall performance. These fittings find utility in both industrial and commercial applications. We manufacture and supply wide range of Tube Fitting such as Compression Fittings, Hydraulic Fittings, Ferrule Fittings, PTFE Tube Fittings, etc. Pipingprojects.us is a top Tube Fitting Supplier in USA. Alongside these fittings can be crafted using alternative materials such as stainless steel, copper, brass, alloy, and carbon steel.

Tube Fitting

Trusted

Supplier

Genuine

Product

Easy

purchase

Want to know more about product?

Contact us now for quick help

What are Tube Fittings?

Tube fittings can be made from a variety of grades, which improves their general performance. We are a top Tube Fitting Manufacturers in USA. Both industrial and instrumentation applications can employ these fittings. In addition to , Tube Fitting can also be crafted from alternative materials such as copper, brass, alloy 400, and carbon steel.

These fittings provide secure and leak-resistant connections, and they come in a range of types, including Hydraulic Fittings, JIC Fittings, High Pressure Fitting, and Air Hose Fittings. Known for their corrosion resistance and durability, tube fittings are commonly used in industries such as chemical processing, petrochemical, and food and beverage, where maintaining hygiene and withstanding harsh environments are crucial considerations.

Pipingprojects.us is a leading Tube Fitting Suppliers in USA. Our products are in various diameters and sizes to meet different needs and purposes.

Want to know more about product?

Contact us now for quick help

High Pressure Tube Fittings Uses & Applications

High-pressure tube fittings are typically used in oil and gas pipelines to handle volatile and pressurized media. High-pressure tube Fitting is used in applications requiring high-performance levels, such as ships and aeroplanes. These fittings are also a feature in the aerospace, power generation, and automotive industries. This Male Elbow fitting is very durable and reliable in its functionality.

Steel-forged flanges and plate flanges have distinct manufacturing processes and applications. Steel-forged flanges are produced by subjecting the material to heat and pressure, which enhances their strength and durability. This makes them ideal for use in high-pressure and high-temperature environments. On the other hand, plate flanges are obtained by cutting them from a flat plate. They are typically thinner, lighter, and more economical, making them suitable for lower-pressure applications.

Tube Fitting - Specifications

Pipingprojects.usa is an esteemed Tube Fitting Manufacturer, is dedicated to providing with reliable, top-notch Tube Fitting. Here are the specifications for Tube Fitting.

| Tube Fitting | Specifications |

|---|---|

| Size | 1/16 OD to 2 OD, Od to 50mm OD |

| Pressure Rating | 1000 Psi, 3000 Psi, 6000 Psi, (3000psi - 10000psi) |

| Schedules | 5S, 10S, THE 40S, 80S, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, and XXS |

| Types | NPT, NPTF, BSPT, BSPP, UN/UNF |

| Grade | |

| Stainless Steel | 200 Series - 201, 202, 205.

300 Series 301, 302, 303, 304, 304L, 308, 309, 309S, 310, 310S, 314, 316, 316L, 316TI, 317, 317L, 321, 347. 400 Series 405, 409, 429, 430, 430F, 430FSe, 434, 436, 442, 446, 403, 410, 414,416, 416Se, 420,420F, 422, 431, 440A, 440B, 440C. 500 Series - 501, 502. 600 Series - 630 (17-4 PH). |

| Titanium | Titanium 6-4, Gr 1, Gr 2, Gr 3, Gr 4, Gr 5, Gr 7, Gr 9, 5-2.5, 6-2-4-2, 6-4 ELI, 6-6-2. |

| Hastelloy | C22, C276, X, B-2. |

| Monel | 400, K500. |

| Nickel Alloy | Nickel 200 Nickel 201, Alloy 20, Alloy 286, Alloy 218 (Nitronic 60), Nitronic 50 (XM-19). |

| Cupro Nickel | Cu 90-10 (C70600,CW352H), Cu 70-30 (C71500, CW354H). |

| Inconel | 601, 625, 660A, 718, X-750, 825, 925, 608. |

| Duplex / Super Duplex | D S31803, D S32205, SD S32750, SD S32760, SD S32950. |

| Chromium Molybdenum Steel | A387 Gr 2, A387 Gr 12, A387 Gr 11, A387 Gr 22, A387 Gr 22L, A387 Gr 7, A387 Gr 21, A387 Gr 21L, A387 Gr 9, A387 Gr 91. |

| Nichrome Alloy | CrNi 20/80. |

| Copper | ASTM B1, ASTM B2, ASTM B3, ASTM B152, ASTM B124, ASTM B133. |

| Brass | Alloy 260, Alloy 272, Alloy 330, Alloy 353, Alloy 360, Alloy C48200 - C48500, Alloy 464. |

| Bronze | Alloy 954, Alloy 933. |

| Case Hardening Steels | 10C4, 15C8, 15Cr3, 16Mn5Cr4, 20MnCr5, 15Ni5Cr4Mo1, 15Ni5Cr4Mo2, 20Ni7Mo2, 20NiCrMo2, 14CrNi6. |

| En Series | En8, En9, En19, En24, En30B, En31, En36, En45, En47, En48. |

| Mild Steel | Sae 4118, Sae 4120, Sae 4120, Sae 4130, Sae 4135, Sae 4137, Sae 4140, Sae 4142, Sae 4145, Sae 4147, Sae 4150, Sae 4161, Sae 8620. |

Why are Pipingprojects.us is the best Tube Fitting Manufacturer & Supplier in USA?

We Follow strict quality control procedures and standards that guarantee good surface and near dimensional tolerances, we manufacture Tube fittings. With ASME Quality and ISO 9001:2015 Certifications, we are a market-leading supplier of carbon steel, alloy steel, and stainless steel Tube Fitting solutions on a global scale. We are a leading Tube Fitting Supplier in USA. We not only produce Tube Fitting of the highest quality, but we are also an authorized dealer of ISMT and Jindal for the supply of carbon steel and alloy steel Tube fittings.

Tube Fittings Size Chart in Mm

| Tube Size (Inches) | Outer Diameter (mm) | Thread Size (NPT) | Thread Size (Metric) | Hex Size (mm) | Wrench Size (mm) |

|---|---|---|---|---|---|

| 1/8 | 3.175 | 1/8 | M10x1.0 | 9 | 14 |

| 1/4 | 6.35 | 1/4 | M12x1.5 | 14 | 19 |

| 3/8 | 9.525 | 3/8 | M14x1.5 | 17 | 22 |

| 1/2 | 12.7 | 1/2 | M16x1.5 | 22 | 27 |

| 5/8 | 15.875 | 5/8 | M18x1.5 | 24 | 30 |

| 3/4 | 19.05 | 3/4 | M20x1.5 | 27 | 32 |

| 1 | 25.4 | 1 | M27x2.0 | 32 | 41 |

Tube Fitting Supplier Design and Equipment Arrangements - Pipingprojects.us

A Tube Fitting is essential in various manufacturing processes, as it is available in multiple specifications. We are a leading Tube Fitting Manufacturers in USA and other countries. The selection of Tube Fitting material for installation is based on its characteristics, including its resistance to chemicals, temperatures (or temperature fluctuations), pressures, acids, gases, and occasionally electromagnetic or electrical forces. Tube Fitting are ubiquitous components and are present in automobiles, trains, aircraft, watercraft, electrical equipment, pumps, and numerous other applications.

Tube Fittings Tolerance Chart

| Tube Fitting Type | Dimensional Tolerance (mm) | Thread Tolerance (mm) | Surface Finish (Ra) | Material Tolerance (mm) | Angular Tolerance (degrees) |

|---|---|---|---|---|---|

| Elbow | ±0.5 | ±0.2 | 0.8μm (32μinch) | ±0.05 | ±1 |

| Connector | ±0.5 | ±0.2 | 1.6μm (63μinch) | ±0.05 | ±1 |

| Union | ±0.5 | ±0.2 | 1.6μm (63μinch) | ±0.05 | ±1 |

| Tee | ±0.5 | ±0.2 | 0.8μm (32μinch) | ±0.05 | ±1 |

| Adapter | ±0.5 | ±0.2 | 1.6μm (63μinch) | ±0.05 | ±1 |

| Coupling | ±0.5 | ±0.2 | 1.6μm (63μinch) | ±0.05 | ±1 |

| Cross | ±0.5 | ±0.2 | 0.8μm (32μinch) | ±0.05 | ±1 |

Advantages & Disadvantages Of Using Compression Fittings

The primary advantage lies in the ease of installation. The compression fitting ferrule ensures a secure seal without necessitating specialized tools, equipment, or soldering. Furthermore, this fitting is relatively inexpensive compared to alternative options. These connections can withstand high temperatures and pressures and exhibit exceptional resistance to vibrations.

Conversely, a hydraulic compression fitting is less robust than a soldered one. Additionally, bending is more challenging unless a thinner-walled tube is utilized. In the latter scenario, the maximum pressure the connection can accommodate will be restricted.

A direct action to address a leakage issue is to re-tighten the nut, effectively eliminating thread corrosion. If this remedy proves ineffective, a replacement is required. Employ pliers to securely grip the male compression fitting and unscrew the nut to accomplish this. Subsequently, loosen the ring and cut through it with a hacksaw if necessary. Finally, install the new nut and ring.

| OD | OD Actual | Thread Designation - Nominal Size | Thread per inch |

|---|---|---|---|

| 5/16 | 0.3125 | 1/16 | 27 |

| 13/32 | 0.405 | 1/8 | 27 |

| 35/64 | 0.549 | 1/4 | 18 |

| 43/64 | 0.675 | 3/8 | 18 |

| 27/32 | 0.840 | 1/2 | 14 |

| 1-3/64 | 1050 | 3/4 | 14 |

| 1-5/16 | 1315 | 1 | 11-1/2 |

| 1-21/32 | 1660 | 1-1/4 | 11-1/2 |

| 1-29/32 | 1900 | 1-1/2 | 11-1/2 |

| 2-3/8 | 2375 | 2 | 8 |

| 2-3/8 | 2875 | 2 | 8 |

| 3-1/2 | 35 | 3 | 8 |

| 4 | 40 | 3-1/2 | 8 |

| 4-1/2 | 45 | 4 | 8 |

| 5-5/8 | 5563 | 5 | 8 |

| 6-5/8 | 6625 | 6 | 8 |

Is NPT male or female?

The American National Pipe Tapered Thread, or NPT, is a widely use for connection in various industries. Comprising both male and female threads, the NPT threaded ferrule fitting is tapered to ensure a secure hydraulic seal. It is imperative to utilize thread sealant when working with NPT to prevent any gaps resulting in spiral leakage, damaging the piping over time. Additionally, selecting appropriate tubing for NPT threaded ferrules is crucial. The material must possess a lengthy service life, be resistant to corrosion, and be compatible with the media. Threaded ferrule fittings are available in ANSI B1.20.1 NPT, ANSI B1.20.3 NPTF, BSPT, and BSPP.

Important Things To Note While Selecting Tube Fitting

Which Industries widely uses Tube Fitting?

Supplying Tube Fitting to Following Cities:

Pipingprojects.us is a leading Tube Fitting Suppliers in USA. We proudly supply high-quality Tube Fitting to major U.S. cities. We have dominated the market as the USA’s leading Tube Fitting Supplier for a long time.

| Cities We Supply | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| New York | Chicago | Los Angeles | San Diego | San Francisco | |||||

| Seattle | Dallas | Houston | Austin | Phoenix | |||||